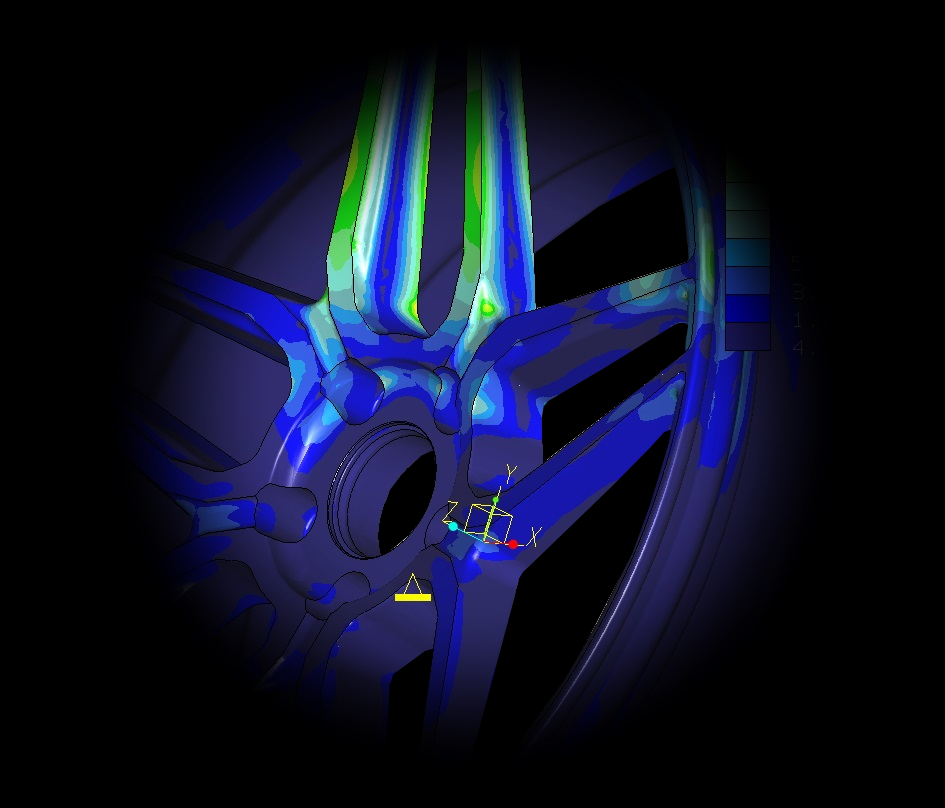

The finished disc and the suitably manufactured rim well now come into the assembly. Extremely strong screwing with the correct torque connects the star to the lip. The screws are either made of stainless steel or titanium – visible or hidden. After joining, the entire 2-piece rim is checked once again for smooth running and the bolted connection for vibration resistance.

The splendid specimen is now finally inspected by our quality representative and sent to the logistics department, where the extensive accessories are included.

A few days later, our customer can enjoy his individual 2 piece Forged wheels which are tailored to his wishes. Whether Mercedes AMG, VW GTI, Lamborghini, Mustang or BMW M – we produce for all bolt circles from 18 – 22″; in widths up to 13J and in offsets from -30 to +70.

WF.FORGED SERIES – BUILT FOR PERFECTION.